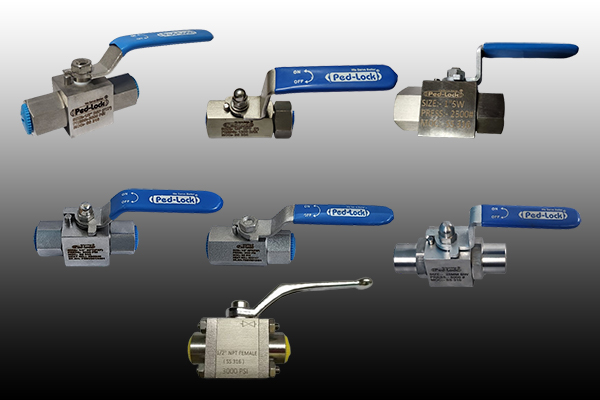

SS Ball Valve Manufacturers

PENAL MOUNTING 3WAY / 2WAY

SPECIFICATIONS :

- Rating : Up to 6,000 psi @ up to 250ºF

- Stem & Body Seal : ‘O-ring (Nitral & Viton)

- Tube Size : 1/4” to 3”

- Connections : Threaded

- Body : Bar Stock & Forged Steel

- Material : SS, CS and other Material Other as Per Your Requirements

Application :

- Chemicals industry

- Fats and fertilizer industry

- Ship building

- Construction industry

Physical Features :

- Pressure rating 400 kg/cm2

Best SS Ball Valve Suppliers

Ped-Lock is committed to manufacturing and supplying engineering products with excellent personal service to our customers. We take pride in innovation, incorporating, reliability and safety to the products. We provide the best professionals solutions for the most demanding industries. In addition of pressure fitting equipment, we manufacture Instrument High Pressure Ball Valves as well.

It's important to note that High Pressure Ball Valves should be distinct from ball-check valves, which serve a different function of preventing backflow. At Ped-Lock, we produce and offer high-quality High Pressure Ball Valves Suppliers in bulk at competitive prices in Andhra Pradesh, Assam, Bihar, Chhattisgarh, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu And Kasmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Odisha, Punjab, Rajasthan, Tamilnadu, Telangana, Uttar Pradesh, Uttarakhand, West Bengal, India.

At Ped-Lock, we are a trusted of ss ball valves manufacturers, suppliers engineered for demanding industrial and hydraulic applications. Designed to withstand extreme pressure conditions, our valves ensure reliable shut-off, flow control, and leak-free operation in even the harshest environments.

Our high pressure ball valves are built using high-grade stainless steel, carbon steel, or customized alloys based on the application requirement. These valves are ideal for hydraulic systems, chemical processing plants, oil & gas pipelines, and other high-pressure flow systems.

Key Features :

- SS 316 construction for corrosion resistance, full or reduced bore for excellent flow. viton seal for better performance.

- Ball hard chrome plated for smooth operation.

Testing :

- For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

- Working pressure : 6000 psi (431 bar)

Hydro Tests :

- Performed with pure water at 1-1/2 times of the working pressure.

- Other tests like helium, seismic are available upon request.